As a special pollution-control and waste-disposal industry, the comprehensive utilization of waste rubber in our country has undergone rough times, and finally it has realized the summary in development, embodied value in creativity, made achievements in struggle, and opened up a path full of vitality and Chinese characteristics. At present, the use of waste rubber in China is mainly divided into three parts: used tire retreading, recycled rubber, and rubber powder. The comprehensive utilization rate of waste rubber has reached more than 75% and is close to that of developed countries. It is the comprehensive utilization of waste rubber industry several generations of unremitting hard work, only to avoid the headaches of black pollution and waste tire piles situation, and scrap tires and rubber waste be recycled.

Recycled rubber opens up a third rubber resource

At present, China's rubber products are favored by countries due to their low price and high quality. The production of these rubber products is inseparable from China's unique low-cost third-rubber resource that is tied with natural rubber and synthetic rubber—recycled rubber. The production of reclaimed rubber is still the main way for the utilization of waste rubber in China, accounting for 90% of the total use of waste rubber in the country.

China's reclaimed rubber industry first appeared in the early 1930s, and the real formation of an industry was after the founding of New China. In 1952, the national production of recycled rubber reached 1,500 tons. Among them, Shanghai Shanglian Rubber Factory's output reached 844 tons, which became China's first formal oil-refined rubber production enterprise. At the same time, the state invested in the construction of a state-owned renewable rubber plant in Shanghai and Shenyang. In 1956, China's annual output of recycled rubber increased by 5,000 tons. Since then, the country has invested in new and expanded reclaimed rubber plants in Handan, Tianjin, and Beijing. In 1960, the output of reclaimed rubber in China reached 23,716 tons, which was 15 times more than in 1952.

In the 1960s, the state began to rationalize the layout of recycled rubber production. New reclaimed rubber plants were successively established in Chongqing, Jinan, Guangzhou, Hunan, etc., making the distribution of recycled rubber in China more reasonable, reducing the use of raw rubber and recycled rubber products. Return transportation. In 1974, the company completed a design plan for an annual production capacity of 3,000 tons of water-oil reclaimed rubber production plants, and set up a large-scale plant.

After the 1980s, China’s reclaimed rubber industry was in a stable development stage. In addition to the 23 key plants that have successively expanded their production capacity, a number of small factories have been built in various parts of the country. In 1985, the output of reclaimed rubber exceeded 150,000 tons, making it the world’s largest producer of recycled rubber. Rubber producer.

With China's accession to the WTO World Trade Organization, the state-owned and collective economy of the reclaimed rubber industry has basically withdrawn during the "Nineth Five-Year", "Tenth Five-year", and "Eleventh Five-Year Plan" periods, and the industry has turned almost exclusively to private, private, and joint-stock companies. In 2014, China’s reclaimed rubber production reached 4.1 million tons, accounting for 72.9% of the world’s reclaimed rubber production.

With the continuous improvement of the environmental requirements of the society and the realization of environmental safety, “turning waste into treasure†will become an important task for the industry. In 2013, the Waste Rubber Comprehensive Utilization Branch of the China Rubber Industry Association proposed three major goals for the green development of reclaimed rubber, namely, the need to eliminate “small three piecesâ€, the use of crushing and smashing equipment without safety hazards, elimination of coal tar, and production of environmentally friendly recycled rubber. Change the desulfurization method to replace the tank on behalf of the tank, that is, the use of continuous atmospheric pressure desulfurization equipment.

At present, China has been able to produce tire reclaimed rubber, rubber shoes reclaimed rubber, sundry recycled rubber, light-colored reclaimed rubber, color reclaimed rubber, odorless reclaimed rubber, latex reclaimed rubber, butyl reclaimed rubber, nitrile regenerated rubber and EPDM regenerated Rubber, etc., used to replace different types of rubber.

In the next 10 years, the reclaimed rubber industry plans to: In 2020, the output of recycled rubber will reach 7.25 million tons, the production of rubber powder will reach 800,000 tons, and the amount of waste rubber handled will reach 9.66 million tons, accounting for 71.55% of the total amount of waste rubber; it will be recycled in 2025. The rubber output reached 10.65 million tons, the production of rubber powder reached 1 million tons, and the amount of waste rubber handled reached 13.98 million tons, accounting for 72.06% of the total use of waste rubber.

Tire retreading to maximize the use of value

Tire retreading is a way to maximize the value of used tires. However, China's tire-lapping industry started relatively late and its development has been slow. In 1928, Tianjin first appeared in two small rubber factories in Tongxing and Beiyang, mainly engaged in the repair of tires, but the workers were only 5 to 6 people, and the rubber materials were purchased from the Japanese companies. In 1948, there were only ten or twenty companies in China, and they were small, technologically backward, and obsolete. Most of the raw materials were imported and concentrated in several major cities such as Guiyang, Chongqing, Shanghai, Tianjin, and Guangzhou.

After the liberation, the new Chinese retreaded enterprises were first handed over from the KMT government, such as Guiyang Tire Renovation Plant, Chongqing Tire Renovation Plant, Shanghai Tire Refining Plant, and Tianjin Tire Renovation Plant; and secondly, new state-owned enterprises established by governments at all levels. For example, the Beijing Tire Renovation Plant built by the Ministry of Communications; the third is a greater number of collectively-owned enterprises and private private enterprises organized by various systems and industries.

Since the early 1970s, in order to meet the needs of China's agricultural mechanization, the retreading industry has expanded from the past mainly for transport and defense services to the renovation of tractor tires and tires. During this period, due to the increasingly prominent contradiction between the supply and demand of tires and the increasing shortage of tires and tires, the state attaches great importance to the retreading industry. Through the reform of tire supply, it has comprehensively strengthened the supply management, use management and retread management of tires. With the strong support of the country, by 1982, there were more than 700 retreaded and fixed-point enterprises in the country, and 5.74 million tires were reloaded. The rapid development of the retreading industry continued until the early 1990s.

After adjustment and transformation, in 2001, there were about 500 companies in the country, including 7 million tires annually and more than 3.6 million tires annually. A tire retreading industry that can revamp truck tires, agricultural tires, construction machinery tires, and aviation tires has begun to take shape, and a number of large-scale, high-tech tire remanufacturing companies have emerged, such as Fujian Xianfeng Rubber Co., Ltd. Company, Chongqing Chaoke Industrial Co., Ltd., Dongguan Hongyun Tire Renovation Factory, etc. However, on the overall level, China’s tire-producing companies generally have a small scale of production and low labor efficiency. The quality of retreading is quite different from that of foreign countries. It has poor product awareness (most trademarks are not on the retreaded tires, brand and quality level), and the appearance is not In addition, the product specification series is not complete. At present, there are thousands of new tire specifications at home and abroad. China can only refurbish dozens of specifications. Many uses and special tires can't be refurbished, and the number of refurbishments is small. Most retreaded tires have a short service life and the mileage is only equivalent to the new tires. 50% (Foreign retreaded tires can reach more than 80% of the mileage of new tires).

At present, China's tire retreading technology has hot vulcanization refurbishment and pre-sulfurization refurbishment, hot vulcanization refurbishment is a traditional technology, pre-sulfurization refurbishment represents the advanced level of the world tire retreading industry. The level of retreading technology and equipment, except for a few companies that can reach the advanced level of the developed countries, is only equivalent to the level of traditional technology of developed countries in the 1980s.

In recent years, with the rapid development of the automobile industry, China has become a world leader in tire production and consumption. In order to maximize the effectiveness of the use of discarded tires, the practice of “refurbishing first and then discarding†is generally used internationally. Constrained by technical equipment and policy standards, China's tire retreading volume accounts for only 5% of the new tire production. The main types of retreaded tires are passenger and cargo truck tires and construction machinery tires. The rate of renovation of these tires in developed countries is generally over 90%. China's car tires are basically not refurbished. The rate of renovation in developed countries is generally 10%, and the rate of renovation in the European Union is 18.8%. According to the level of technology and equipment for tire retreading in developed countries, the proportion of radial tires with high refurbishment rates in China is at least 10 to 20 years behind.

The reasons for the relatively low rate of tire retreading in China are: tire consumption concept is conservative, and new tires are ignored while retreaded tires are ignored. The quality of retreaded tires is not recognized; too few retreadable tires are available; the recycling channels for used tires are poor.

With the promulgation of the "Tire Retreading Industry Access Requirements", "Waste Tire Comprehensive Utilization Industry Access Conditions", and "Provisional Measures for the Administration of Admission Notification of Waste Tire Comprehensive Utilization Industry", China's tire retreading industry will usher in new developments. Opportunity, “small but complete†workshop-style enterprises have already withdrawn from the stage of history, the industrial concentration will be significantly improved, and large-scale enterprises will be supported by national policies.

The development plan for China's tire retreading industry is: In 2020, the scale of tire retreading will reach 25 million, and the refurbishment rate will reach 40%; in 2025, the refurbishment rate will reach more than 60%, which will reach the tire retread rate in developed countries.

We can produce and process the Stamping Parts according to your any requirements of materials, specifications, shapes, surfaces, packagings( and so on).

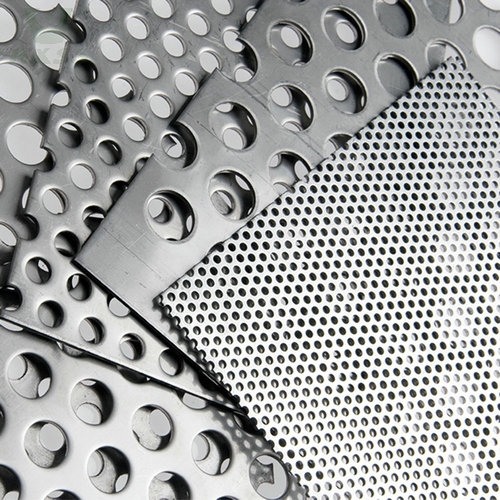

1) Material : Our Perforated Metal Sheet always choose premium raw material

include stainless steel sheet, iron sheet, galvanized metal sheet aluminum sheet and so on.

2) Hole Pattern : The perforated Hole Pattern we can do:Round, Rectangular,Square, Triangle, Diamond, Hexagonal, Cross, Slotted and any other special patterns.

3) Applications : The perforated metal sheets can regularly used for screening,decoration, sifting, filtration, drying, cooling, cleaning and any other applications.

4) Customizable : The hole pattern, sheet size, raw material of perforated metal sheetcan precisely made according to the customers' specifications.

5) The factors in Quotation:

*Perforated Hole Pattern

*Sheet shape & size

*Raw material

*Unique Requirements

*Applications

*Any specifications you need concern the products.

Perforated Sheet,Perforated Metal Sheet,Perforated Steel Sheet

Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.shaiwanghaoxiang.com