CoreTech System is dedicated to providing high-quality molding simulation software — Moldex3D, a powerful product to assist mold designers and injection molding engineers. Now, we’re expanding our reach to product designers with the innovative cloud platform — Moldiverse. This platform contains a plastic material database, machine data management platform and a plastic professional knowledge resource, enabling designers to identify optimized product parameters, reducing product development cycles and enhancing collaboration efficiency.

Fig 1 Moldiverse assists product designers in improving efficiency

Material Hub Cloud (MHC) – Addressing All Your Plastic Material Challenges

MHC currently provides over 9,000 materials and counting. With several professional features, such as Alternative Material, Material Comparison and Material Selection Guidance, it assists nearly 10,000 users each month in dealing with issues related to plastic materials. This year, we’ve added several practical features, including the ability to search for thermoset materials in the Material Database Viewer and to compare both physical and mechanical properties simultaneously. Additionally, the clamping force and cavity pressure in the Clamping Force Advisor can suggest a suitable injection machine tonnage with input material properties. In the future, we will continue to add various practical features, ensuring that selecting plastic materials will no longer be a challenge.

Fig 2 An online learning platform for plastic and molding knowledge

University ï¼ Your On-Demand Resources for Plastics Expertise

Stay up to date with the latest knowledge in plastic manufacturing through Moldex3D University in Moldiverse. This platform offers a variety of self-learning resources to meet your specific needs, including years of industry experiences, selected webinars, and training materials. Furthermore, we released the feature Documentation this year, which offers user guides for Moldex3D products and integration tools for molding analysis. Users can quickly browse and download essential information know-how and immediately apply it into their work.

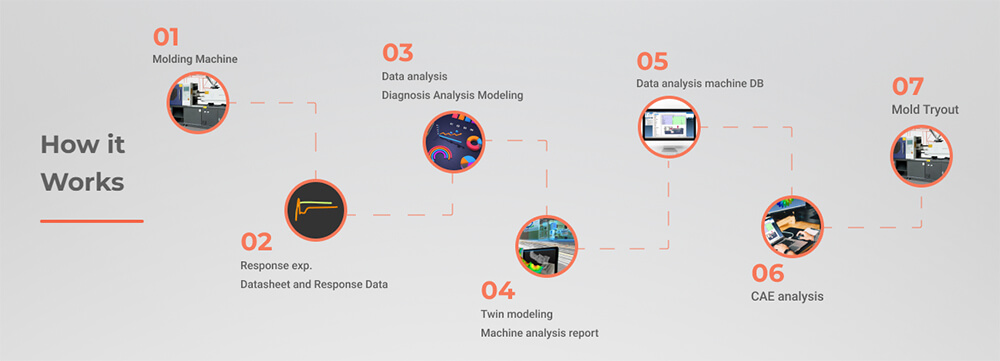

Fig 3 The Basic Workflow of iMolding Hub

iMolding Hub ï¼Creating Digital Twins, Connecting Machine and Simulation

Building a unique digital twin for each machine is a crucial step toward Industry 4.0.  In Moldex3D’s iMolding Hub, users can upload machine data first, then match with industry-leading Moldex3D Machine Characterization services to create a digital twin for each machine. After submitting data in the iMolding Hub, users can download machine characteristic reports and analysis documents from the web. This enables them to employ each machine’s unique performance and dynamic response in CAE molding analysis, generating optimized conditions that closely matches with real production. Using just a smartphone or tablet, users can capture machine characteristics, improve efficiency, and save time.

Fig 4 Forum promotes knowledge sharing within the plastics industry

Forum ï¼ A Platform for the Plastics Industry to Exchange Ideas

Moldiverse’s new Forum is designed to foster knowledge sharing and technical exchange. This platform, specially created for professionals seeking advanced plastic knowledge, brings the molding community together through up-to-date technical information regarding simulation and general molding knowledge. On the Moldiverse Forum, users can quickly access relevant discussion sections through four main categories and intuitively find the information they need. Each discussion displays the number of replies and likes. Moreover, Forum includes hot questions to help users stay updated on industry development and popular issues. Whether you are facing technical challenges or software option questions, Forum offers detailed direct answers from professionals, ensuring any question you encounter can be resolved promptly.

Fig 5 Moldiverse enables real-time teams’ collaboration

Moldiverse allows teams of all sizes to collaborate seamlessly during the entire production cycle and helps overcome design and manufacturing challenges. With a single account, you can approach all cloud services, obtain comprehensive material data, access learning resources, and achieve intelligent molding and management. Try Moldiverse out today and delve into the broad universe of the plastics industry and molding simulation.

Silicone E-shaped 9-shaped P-shaped

Rubber Sealing Strips,Rubber Strip Seal,Silicone Seal Strip

HEBEI JIEXING RUBBER SEALS CO.,LTD , https://www.jiexingrubber.com